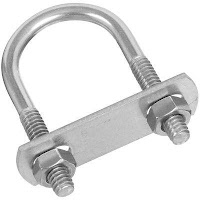

U Bolt is a U-shaped fastener that is used for fastening two or more objects together. It has two threaded arms protruding from a curved base. It has so many uses and therefore, a variety of its sizes are offered by the U Bolt Manufacturers. All its designs are made of different types of metals and the choice of metal based on a number of factors, especially its use and installation environment. Due to its u shape design, it’s both the threaded arms get secured with the help of nuts and they are mainly used with screw and washers.

They not only used for attaching various items to poles or to attach cables to walls, but also for concrete fastening. It’s u shape design keep it in its place for a longer period and help you reap its actual benefits. It gives security and stability to the object, which makes a number of users fall in love with this type of bolt fastener. In an order to reduce unnecessary loss or damage to the application, you should use the right type of bolt as per the need of the task.

Make sure you identify properly whether you want to use it for heavy duty application or light, at what environment and other factors to buy a right option. Ferry International – a trusted Bolt Manufacturers have different types of fasteners to offer. Now, after you know about u bolt and its use in your application, if you want to place your order, dial our number and talk to our executives. You can even drop your email and we will reply as soon as we can.

They not only used for attaching various items to poles or to attach cables to walls, but also for concrete fastening. It’s u shape design keep it in its place for a longer period and help you reap its actual benefits. It gives security and stability to the object, which makes a number of users fall in love with this type of bolt fastener. In an order to reduce unnecessary loss or damage to the application, you should use the right type of bolt as per the need of the task.

Make sure you identify properly whether you want to use it for heavy duty application or light, at what environment and other factors to buy a right option. Ferry International – a trusted Bolt Manufacturers have different types of fasteners to offer. Now, after you know about u bolt and its use in your application, if you want to place your order, dial our number and talk to our executives. You can even drop your email and we will reply as soon as we can.